The Ministry of Electronics and Information Technology (MeitY) has recently presented a policy paper with an intention to replace the existing linear system with a circular economy. The paper, “Circular Economy in Electronics and Electrical Sector,” proposes a paradigm shift in the electrical and electronics manufacturing sector with a circular economy to deal with e-waste.

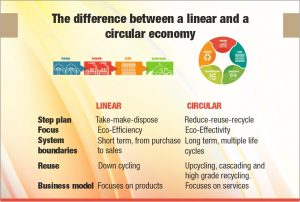

“It serves as an alternative to the current model of highly extractive and resource-intensive linear economy, and aims at maintaining and retaining value of resources, products and materials at their highest by keeping them in use as long as possible,” MeitY said in its policy paper.

Circular economy as a concept has been gaining ground globally. It uses a superior methodology of extracting the maximum value of electrical and electronic products by reusing, repairing, recovering, re-manufacturing and regenerating products and materials at the end of each service value, instead of simply extracting materials. It intends to replace the current linear system of ‘take-make-dispose’ in the electrical and electronics manufacturing sector.

“India is the third largest consumer of raw materials produced globally and estimated to consume nearly 15 billion tonnes of material by 2030 with the current economic trends. Electronic and Electrical Equipment (EEE)-manufacturing is dependent on high material consumption with metals like iron, copper, silver, gold, aluminum, manganese, chromium and zinc along with various rare earth elements. The rate of extraction of these abiotic resources for EEE manufacturing is significantly higher than the rate of their formation in nature. CE approach will thus be imperative to fulfill the resource needs for the country,” the policy paper mentioned.

As per the proposed action plan, the makers of electrical and electronic products would be incentivised to make products with modular designs to reduce fast obsolescence of products and resources. The plan also focuses on mining of raw materials from electrical and electronic waste generated in urban areas so that manufacturers get continued access to such rare earth metals and other costly minerals at low cost.

“Thus, critical materials including rare earth elements needed for manufacturing of EEE (Electronic and Electrical Equipment) products, solar panels, electric vehicles, and many high-tech defence equipment when mined from the e-waste offers great opportunity for securing availability of these resources in future,” MeitY said.

A mechanism to incentivise the producer through rebate schemes for using recycled products back in the manufacturing process can be implemented. This will add the value proposition to the e-waste value chain and producers will be more inclined towards buyback schemes as it will directly get them the product, with increased value return from raw material extracted cost from the waste,” the ministry noted.

The ministry is also likely to formulate a framework to bring in informal players such as e-waste collectors, aggregators, dealers, retailers, online marketplaces, and auctioning platforms.

The paper covers the entire lifecycle of the products used in EEE manufacturing, and makes short, medium and long term suggestions about CE. For example, in raw material procurement, it recommends mandatory use of a certain percentage of critical materials sources from secondary materials, the medium to long term, and promotion of technology for extraction of maximum number of materials through technology development/transfer, innovative finance mechanisms and schemes.

In the consumption stage, the policy recommendations include resource efficiency or circular economy labeling, eco-labelling on the products in the percentage use of recycled materials in the product to create consumer awareness in recycling aspects of products.

It further recommends regulation to increase EEE warranty from 2 to 6 years, measures against planned obsolescence, legal warranty of second-hand products and promoting green public procurement (GPP) by government agencies.

India produced 2.6 kg e-waste per capita in 2019, while it has around 312 authorised e-waste recyclers, according to the latest data from Global E-Waste Monitor, released in July 2020.

It is estimated that a circular economy path adopted by India could bring in annual benefits of 40 lakh crores or approximately US$ 624 billion in 2050. The greenhouse emission would reduce by 44% along with significant reduction in congestion and pollution. Thus contributing to health and economic benefits to the society.

Obsolescence

Obsolescence is a concept when a company plans for a product to become obsolete after a certain point. Manufacturers and service vendors force updates that cause older models to become slow or unusable or stop producing the associated support.

The concept of planned obsolescence isn’t negative in nature. In fact, it’s part of a natural process for a company—any asset management practice will account for end-of-lifting a product. There is no point providing continuing support for an outdated operating system that hardly anyone uses.

But sometimes it is problematic when companies plan to force users to move onto new hardware and software without a good reason, at least from consumers’ point of view. It invites criticism for creating waste without need. This failure to give consumers the ability to ensure the continued use of their products has led to the ‘Right to Repair’ debate.

Right to Repair

Instead of being forced to buy entirely new products, some users want to be able to purchase devices that can be upgraded over their lifespan. This would include being able to upgrade all aspects of the device, including the processing power, memory, and batteries.

This concept is known as the Right to Repair, and it’s something that people in many countries are demanding legislation. Depending on the products you want to repair, you may or may not actually have that right.

Some companies refuse to release the parts necessary to perform repairs and upgrades. That necessarily means that consumers simply can’t fix a product they own. Instead, they need to turn to the company itself or to third-party vendors that can work on devices.

In India, amendments to the Indian Copyright Act of 1952 and the IT Act of 2002 are needed in order to facilitate use of open software, which would enable users to extend usage of their devices for a longer time.

EEE waste is considered as one of the rich sources of secondary raw materials and can contribute towards resource security and environmental sustainability. India is the third most electronic waste (e-waste) generated country (with 3.2 million tonnes in 2019), however, only 10 per cent of the waste is collected for recycling. The collection and management of EEE waste remain a key challenge. This necessitates the shift to a more circular approach for the sector.

India can tackle systemic challenges which can lead to integration of circularity principles in design, manufacturing, consumption and finally end of life management of products wherein it can ensure recovery and utilization of secondary raw materials, circular products with longer use-life, quality assurance for repair and refurbished products, investment in its labour force and advanced recycling technology to mine secondary materials from e-waste, enabling circular growth in electronic production and hence resulting in enriched livelihood, enhanced quality of life and sustainable access to resources.